The MS 6.1 EVO engine control unit manages gasoline engines up to 12 cylinders. As a member of our MS 6 family it features a powerful digital processing core with floating point arithmetic and a high-end FPGA for ultimate performance and flexibility. The MS 6 family utilizes a new software development process based on MATLAB/Simulink which significantly speeds algorithm development by using automatic code and documentation generation. Custom functions can be quickly and easily generated. The flexible hardware design allows the MS 6.1 EVO to support complex or unusual engine or chassis configurations.

- Downloads

- Features

- Application

- Technical Specifications

- Communication

- Installation Notes

- Ordering Information

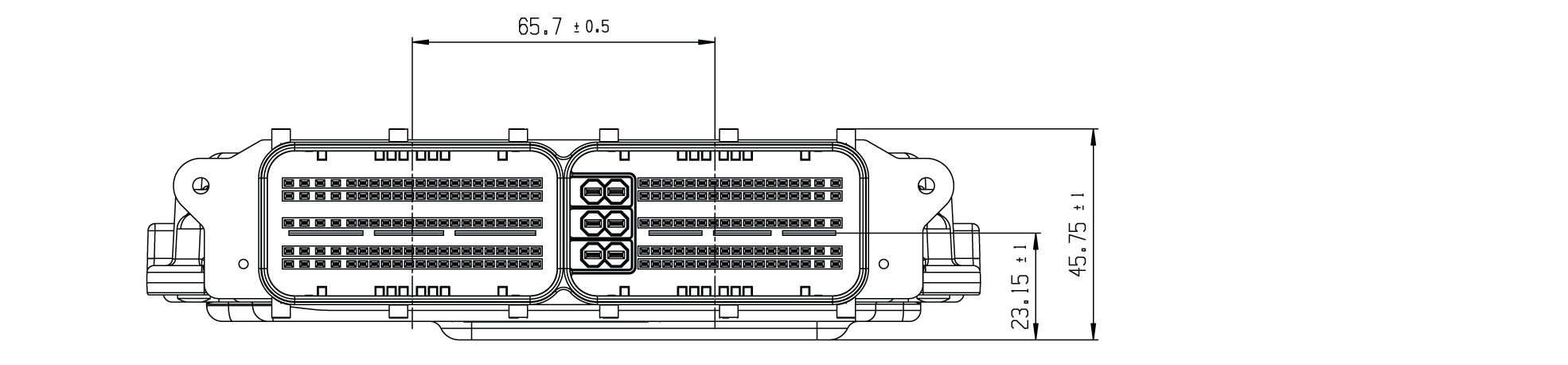

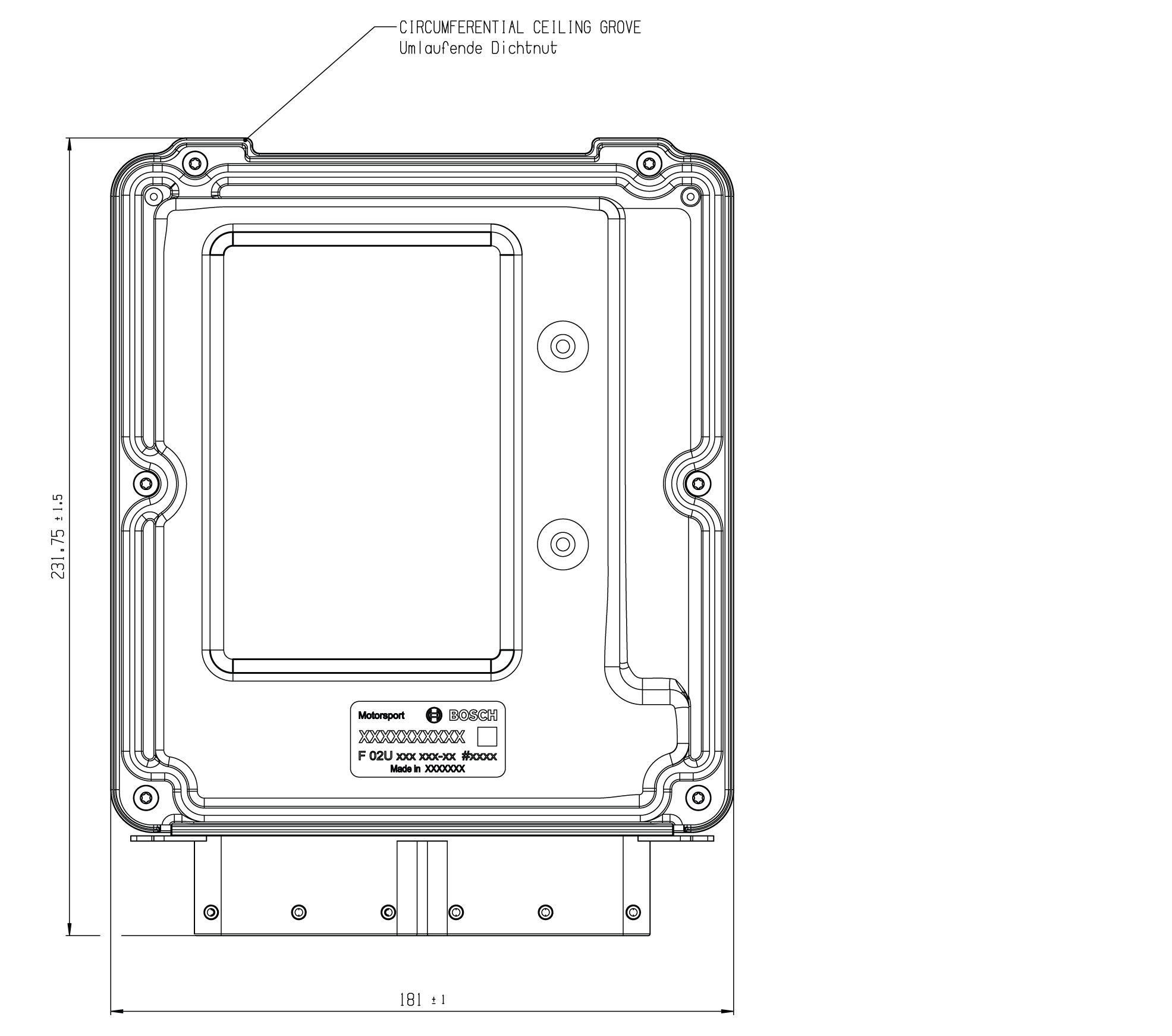

- Dimensions

- Upgrades

- Legal Restrictions

Downloads

To get latest firmware, please contact your customer account manager or send an email to motorsport@bosch.com

Literature

Features

- Optimized for low-pressure injection

- Measurement with 21 analog inputs

- Supports Customer Code Area CCA

- 4 GB memory plus 4 GB upgrade

- SENT sensor support

Application

Low pressure injection

| |

Ignition

| |

Physical engine model for fast application

| |

Integrated support of manual gearshift | |

Electronic throttle control | Optional, see Upgrades |

Variable Valve Timing VVT | Optional, see Upgrades |

Turbo control | Optional, see Upgrades |

Traction control | Optional, see Upgrades |

Launch control | Optional, see Upgrades |

LTE Ethernet telemetry support | |

Internal logger

| |

Logging rates

| |

Technical Specifications

Mechanical Data

Aluminum housing | |

2 Bosch connectors | 196 pins in total |

Size | 226 x 181 x 44 mm |

Weight | 1,086 g |

Protection Classification | IP54 |

Temp. range (at internal sensors) | -20 to 80°C |

Electrical Data

Power supply | 6 to 18 V |

CPU | Dual Core 667 MHz, FPGA |

Inputs

21 analog inputs | |

| 6 x reserved for electronic throttle controls |

| 3 x no integrated pull-up |

| 3 x option for angle synchronous measurement, no integrated pull-up |

| 4 x fixed 3.01 kOhm pull-up |

| 5 x switchable 3.01 kOhm pull-up |

6 internal measurements | |

| 1 x ambient pressure |

| 1 x acceleration 6-axis |

| 2 x ECU temperature |

| 2 x ECU voltage |

8 function related inputs | |

| 1 x Thermocouple exhaust gas temperature sensors (K-type) |

| 2 x Lambda interfaces for LSU 4.9 sensor types |

| 1 x Lap trigger/beacon input |

| 4 x Knock sensors |

18 digital inputs | |

| 1 x switchable Hall or inductive sensor for flywheel measurement |

| 2 x Hall sensor for sync wheel detection |

| 4 x switchable Hall or DF11 sensors for camshaft position or wheel speed |

| 2 x switchable Hall or inductive sensors for turbo speed measurement |

| 1 x digital switch for engine ON/OFF |

| 8 x digital, e.g. SENT |

Sensor supplies and screens

4 x sensor supplies 5 V / 50 mA |

3 x sensor supplies 5 V / 150 mA |

7 x sensor grounds |

2 x sensor screens |

Outputs

28 function related outputs | |

Low Pressure Injection | |

| 12 x 2.2 A controls, high impedance injectors |

Ignition | |

| 12 x control, IGBT or BJT, coils with integrated amplifier |

2 x 8.5 A H-bridge reserved for electronic throttle | |

2 x 4 A pwm lowside switch for Lambda heater | |

19 freely configurable outputs | |

| 1 x 8.5 A H-bridge |

| 2 x 4 A pwm lowside switch |

| 4 x 3 A pwm lowside switch |

| 8 x 2.2 A pwm lowside switch |

| 4 x 1 A pwm lowside switch |

3 output signals | |

| 1 x engine rpm |

| 1 x flywheel |

| 1 x trigger wheel |

Software Tools (free download)

Data Analysis tool WinDarab V7 |

System Configuration tool RaceCon 2.7.0.9 or later |

Mating Connectors (not included)

Mating Connector 91 pins | F02U.B00.711-01 |

Mating Connector 105 pins | F02U.B00.712-01 |

Norms

Product Safety |

EN IEC 62368-1:2020+A11:2020 |

Materials |

REACH - Nr. 1907/2006 |

EMC |

UNECE10:rev.6/AMD1:2020 |

KN41 |

ISO11452-2 |

ISO11452-4 |

ISO10605 |

ISO7637-2 |

ISO7367-3 |

ISO16750-2 |

US FCC: Title 47, Part 15 Subpart B |

ICES-003 |

Testing |

SAEJ1211 |

Communication

2 Ethernet |

3 CAN |

1 LIN |

8 SENT |

1 RS232 |

1 Time sync synchronization Ethernet |

3 Communication screens |

Installation Notes

Maintenance Interval: 220 h or a maximum of two years |

Depending on your experiences with calibration of ECUs, we recommend calibration support from Bosch Motorsport. |

Please remember that the mating connectors and the programming interface MSA-Box II are not included and must be ordered separately. |

Application |

Function documentation |

MatLab code generation |

Ordering Information

Engine Control Unit MS 6.1 EVO

Order number: F02U.V03.113-01

Rugged USB flash drive

Order number: F02U.V03.534-01

Connector for USB flash drive on car loom side

Order number: F02U.002.996-01

Adapter cable to PC USB-Port

Order number: F02U.V01.343-01

Software Options

Engine Function Package 1

Order number: F02U.V02.001-01

Engine Function Package 2

Order number: F02U.V02.002-01

Measurement Package

Order number: F02U.V02.000-01

CCA Hardware Upgrade per device

Order number: F02U.V02.137-01

FULL_LOG_1

Order number: F02U.V02.304-01

FULL_LOG_2

Order number: F02U.V02.305-01

Gear Control Package 1

Order number: please contact MEGA-Line

Gear Control Package 2

Order number: F02U.V02.108-01

SW Package MS 6 Drag 1

Order number: F02U.V0U.409-01

SW Package MS 6 Drag 2

Order number: F02U.V0U.410-01

Innovation License Device

Order number: F02U.V02.510-01

Innovation Package Project

Order number: F02U.V02.511-01

DATA_USB

Order number: F02U.V03.476-01

Accessories

Breakout Box BOB MS 6 EVO

Order number: F02U.V02.294-02

Mating Connector 91 pins

Order number: F02U.B00.711-01

Mating Connector 105 pins

Order number: F02U.B00.712-01

Dimensions

Upgrades

Engine Function Package 1

|

Engine Function Package 2

|

Measurement Package

17 Additional analog inputs

|

Extension of the use of 8 digital channels as analogue / digital inputs (shared) |

1 Additional function related inputs

|

CCA Hardware Upgrade per device

Provides the option to run customer developed software code on Bosch ECU |

FULL_LOG_1

Extension for Partition 1

|

FULL_LOG_2

Activation of Partition 2

|

Gear Control Package 1

Gear control MEGA-Line functionality, has to be used with MEGA-Line components (License model via MEGA-Line) |

Gear Control Package 2

Gear control Bosch Motorsport functionality |

SW Package MS 6 Drag 1

|

SW Package MS 6 Drag 2 (requires Drag 1 License)

|

Innovation License Device

Activation of a set of additional functions for a single device:

|

Innovation Package Project

Innovation Package Project has the same content as Innovation License Device, but license is valid for the whole project instead of a single device |

DATA_USB

Data copy to USB flash drive |

Legal Restrictions

The sale of this product in Mexico is prohibited.

Due to embargo restrictions, sale of this product in Russia, Belarus, Iran, Syria, and North Korea is prohibited.