The MS 6 CUP EVO engine control unit manages gasoline engines up to 4 cylinders. As a member of our MS 6 family it features a powerful digital processing core with floating point arithmetic and a high-end FPGA for ultimate performance and flexibility. The MS 6 family utilizes a new software development process based on MATLAB/Simulink which significantly speeds algorithm development by using automatic code and documentation generation. Custom functions can be quickly and easily generated. The flexible hardware design allows the MS 6 CUP EVO to support complex or unusual engine or chassis configurations.

- Downloads

- Features

- Application

- Technical Specifications

- Communication

- Installation Notes

- Ordering Information

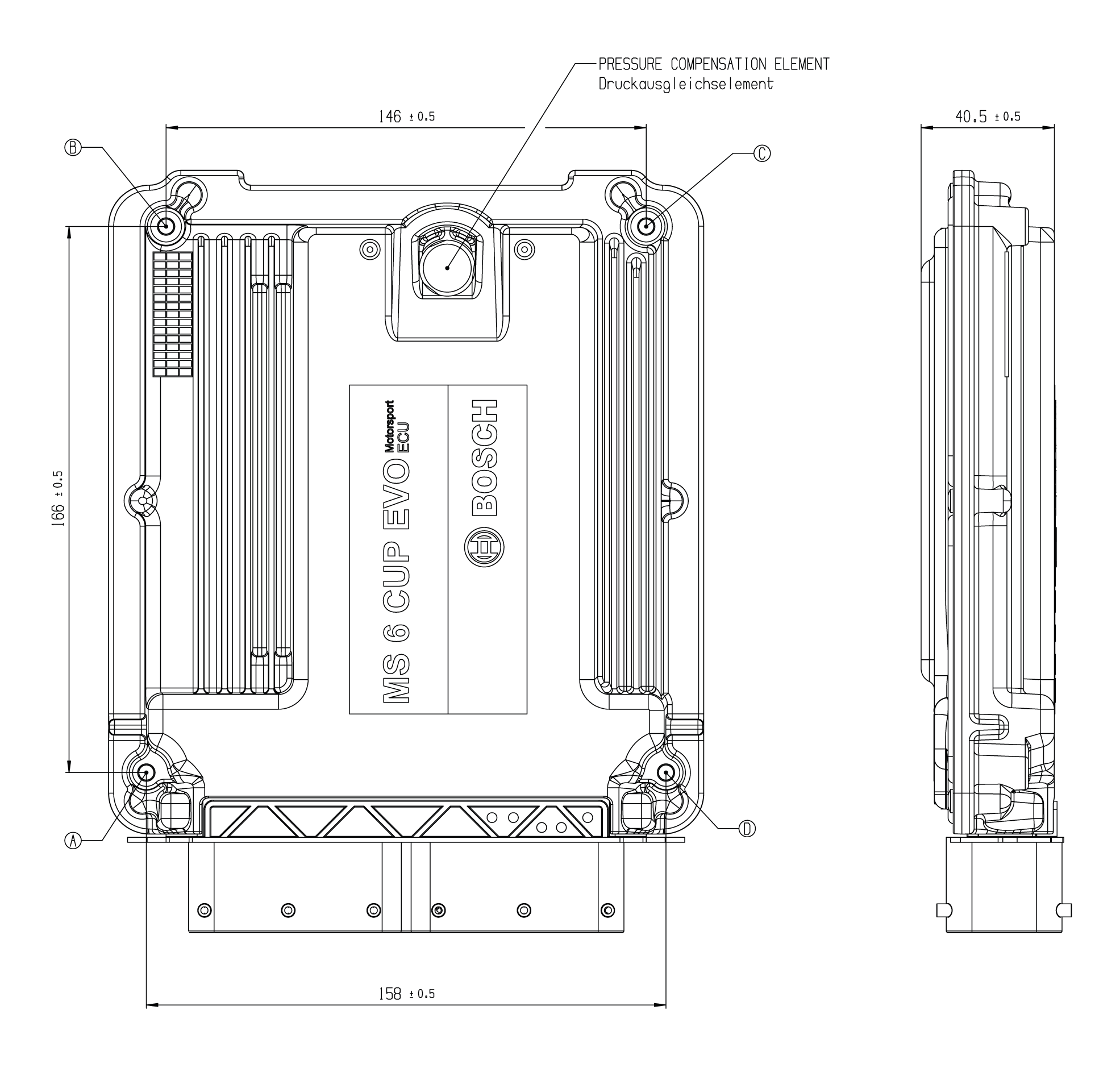

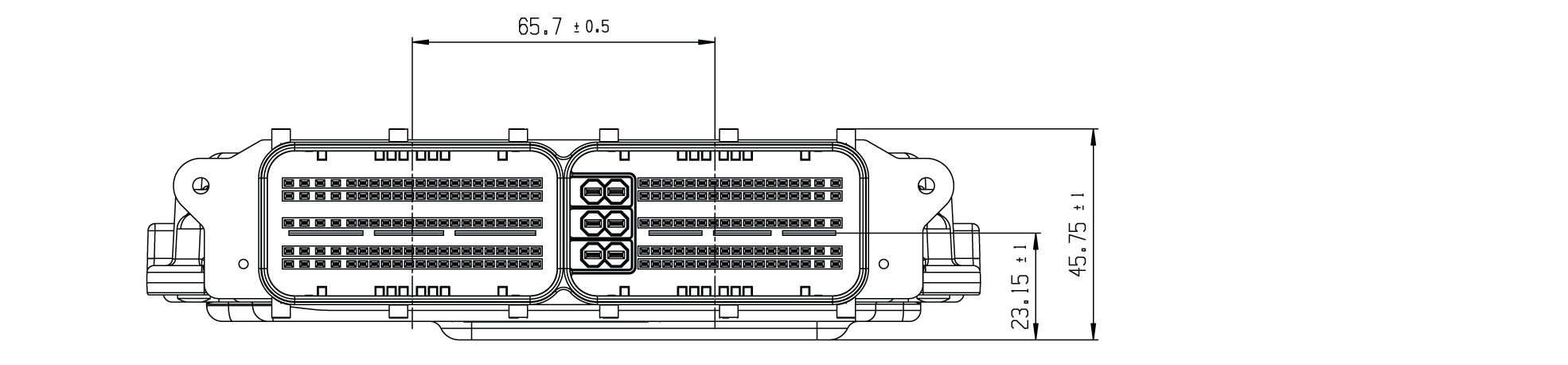

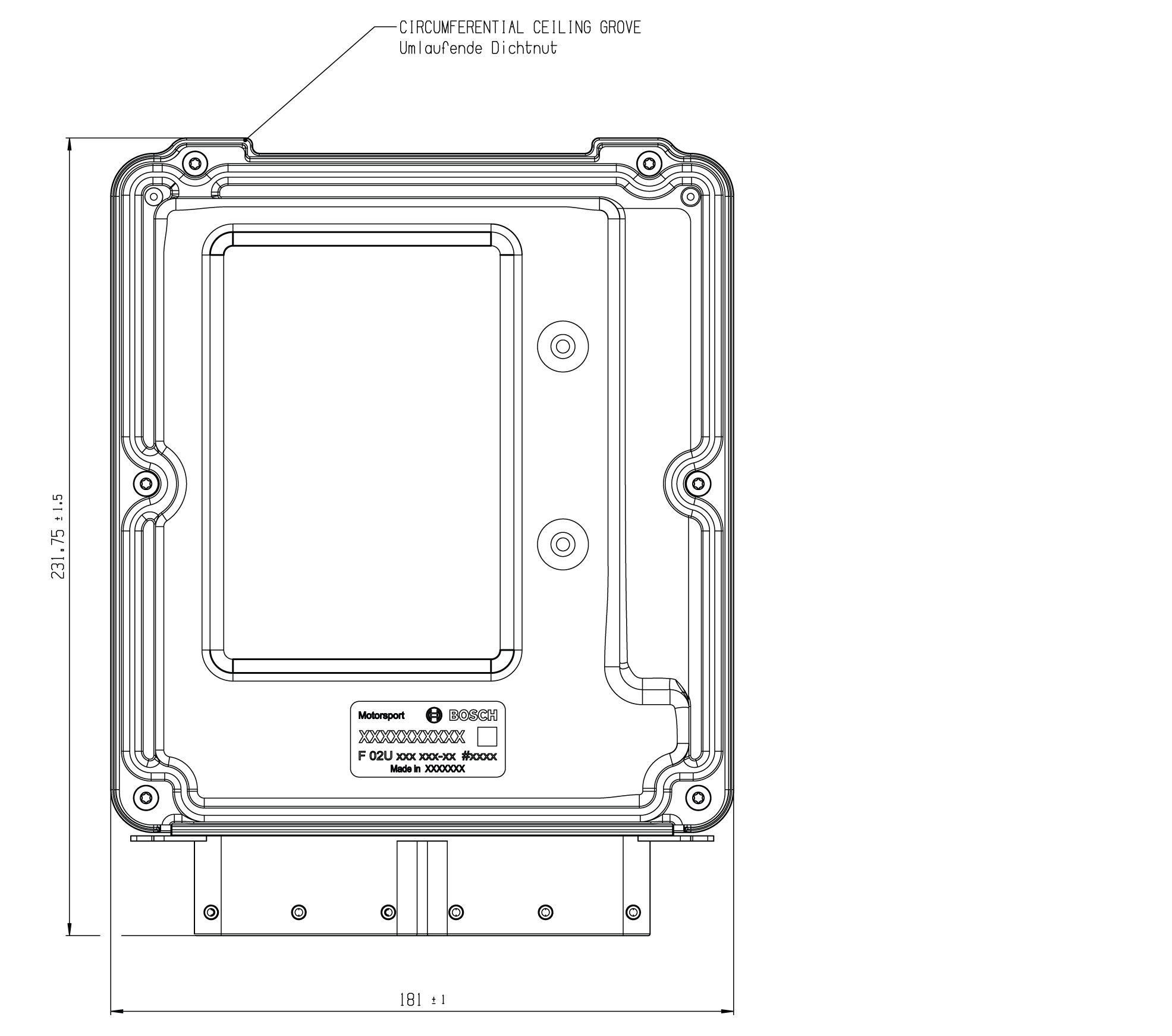

- Dimensions

- Upgrades

- Legal Restrictions

Downloads

To get latest firmware, please contact your customer account manager or send an email to motorsport@bosch.com

Literature

Features

- Delivery for OEM with project-specific program status

- HP package for 4-cylinder engines

- Supports Customer Code Area CCA

- 8 GB memory

- SENT sensor support

Application

High pressure injection

|

Low pressure injection

|

Ignition

|

Physical engine model for fast application

|

Integrated support of manual gearshift |

Electronic throttle control |

Variable Valve Timing VVT |

Turbo control |

Traction control |

Launch control |

LTE Ethernet telemetry support |

Internal logger Partition 1

|

Internal logger Partition 2

|

Logging rates

|

Technical Specifications

Mechanical Data

Aluminum housing | |

2 Bosch connectors | 196 pins in total |

Size | 226 x 181 x 44 mm |

Weight | 1,086 g |

Protection Classification | IP54 |

Temp. range (at internal sensors) | -20 to 80°C |

Electrical Data

Power supply | 6 to 18 V |

CPU | Dual Core 667 MHz, FPGA |

Inputs

26 analog inputs | |

| 4 x reserved for electronic throttle controls |

| 5 x no integrated pull-up |

| 3 x option for angle synchronous measurement, no integrated pull-up |

| 4 x fixed 3.01 kOhm pull-up |

| 10 x switchable 3.01 kOhm pull-up |

6 internal measurements | |

| 1 x ambient pressure |

| 1 x acceleration 6-axis |

| 2 x ECU temperature |

| 2 x ECU voltage |

4 function related inputs | |

| 1 x Thermocouple exhaust gas temperature sensor (K-type) |

| 1 x Lambda interface for LSU 4.9 sensor type |

| 2 x Knock sensors |

18 digital inputs | |

| 1 x switchable Hall or inductive sensor for flywheel measurement |

| 2 x Hall sensor for sync wheel detection |

| 4 x switchable Hall or DF11 sensors for camshaft position or wheel speed |

| 2 x switchable Hall or inductive sensors for turbo speed measurement |

| 1 x digital switch Engine ON/OFF |

| 8 x digital, e.g. SENT |

Sensor supplies and screens

4 x sensor supplies 5 V, 50 mA |

3 x sensor supplies 5 V, 150 mA |

7 x sensor grounds |

2 x sensor screens |

Outputs

15 function related outputs | |

High Pressure Injection | |

| 4 x controls, magnetic injectors 1 x high pressure pump with MSV control |

Low Pressure Injection | |

| 4 x controls, high impedance injectors |

Ignition | |

| 4 x controls, IGBT or BJT, coils with integrated amplifier |

1 x 8.5 A H-bridge reserved for electronic throttle | |

1 x 4 A pwm lowside switch for Lambda heater | |

13 freely configurable outputs | |

| 2 x 8.5 A H-bridge |

| 1 x 4 A pwm lowside switch |

| 2 x 3 A pwm lowside switch |

| 5 x 2.2 A pwm lowside switch |

| 3 x 1 A pwm lowside switch |

3 outputs signals | |

| 1 x engine rpm |

| 1 x flywheel |

| 1 x trigger wheel |

Software Tools (free download)

Data Analysis tool WinDarab V7 |

System Configuration tool RaceCon 2.7.0.9 or later |

Mating Connectors (not included)

Mating Connector 91 pins | F02U.B00.711-01 |

Mating Connector 105 pins | F02U.B00.712-01 |

Norms

Product Safety |

EN IEC 62368-1:2020+A11:2020 |

Materials |

REACH - Nr. 1907/2006 |

EMC |

UNECE10:rev.6/AMD1:2020 |

KN41 |

ISO11452-2 |

ISO11452-4 |

ISO10605 |

ISO7637-2 |

ISO7367-3 |

ISO16750-2 |

US FCC: Title 47, Part 15 Subpart B |

ICES-003 |

Testing |

SAEJ1211 |

Communication

2 Ethernet |

3 CAN |

1 LIN |

8 SENT |

1 RS232 |

1 Time sync synchronization Ethernet |

3 Communication screens |

Installation Notes

Ordering Information

Engine Control Unit MS 6 CUP EVO

Order number: F02U.V03.111-01

Rugged USB flash drive

Order number: F02U.V03.534-01

Connector for USB flash drive on car loom side

Order number: F02U.002.996-01

Adapter cable to PC USB-Port

Order number: F02U.V01.343-01

Software Options

CCA Hardware Upgrade per device

Order number: F02U.V02.137-01

FULL_LOG_1

Order number: F02U.V02.304-01

FULL_LOG_2

Order number: F02U.V02.305-01

Gear Control

Order number: on request

Innovation License Device

Order number: F02U.V02.510-01

Innovation Package Project

Order number: F02U.V02.511-01

DATA_USB

Order number: F02U.V03.476-01

Accessories

Breakout Box BOB MS 6 EVO

Order number: F02U.V02.294-02

Mating Connector 91 pins

Order number: F02U.B00.711-01

Mating Connector 105 pins

Order number: F02U.B00.712-01

Dimensions

Upgrades

CCA Hardware Upgrade per device

Provides the option to run customer developed software code on Bosch ECU |

FULL_LOG_1

Extension for Partition 1

|

FULL_LOG_2

Extension for Partition 2

|

Gear Control

Project individual option |

Innovation License Device

Activation of a set of additional functions for a single device:

|

Innovation Package Project

Innovation Package Project has the same content as Innovation License Device, but license is valid for the whole project instead of a single device |

DATA_USB

Data copy to USB flash drive |

Legal Restrictions

The sale of this product in Mexico is prohibited.

Due to embargo restrictions, sale of this product in Russia, Belarus, Iran, Syria, and North Korea is prohibited.